Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

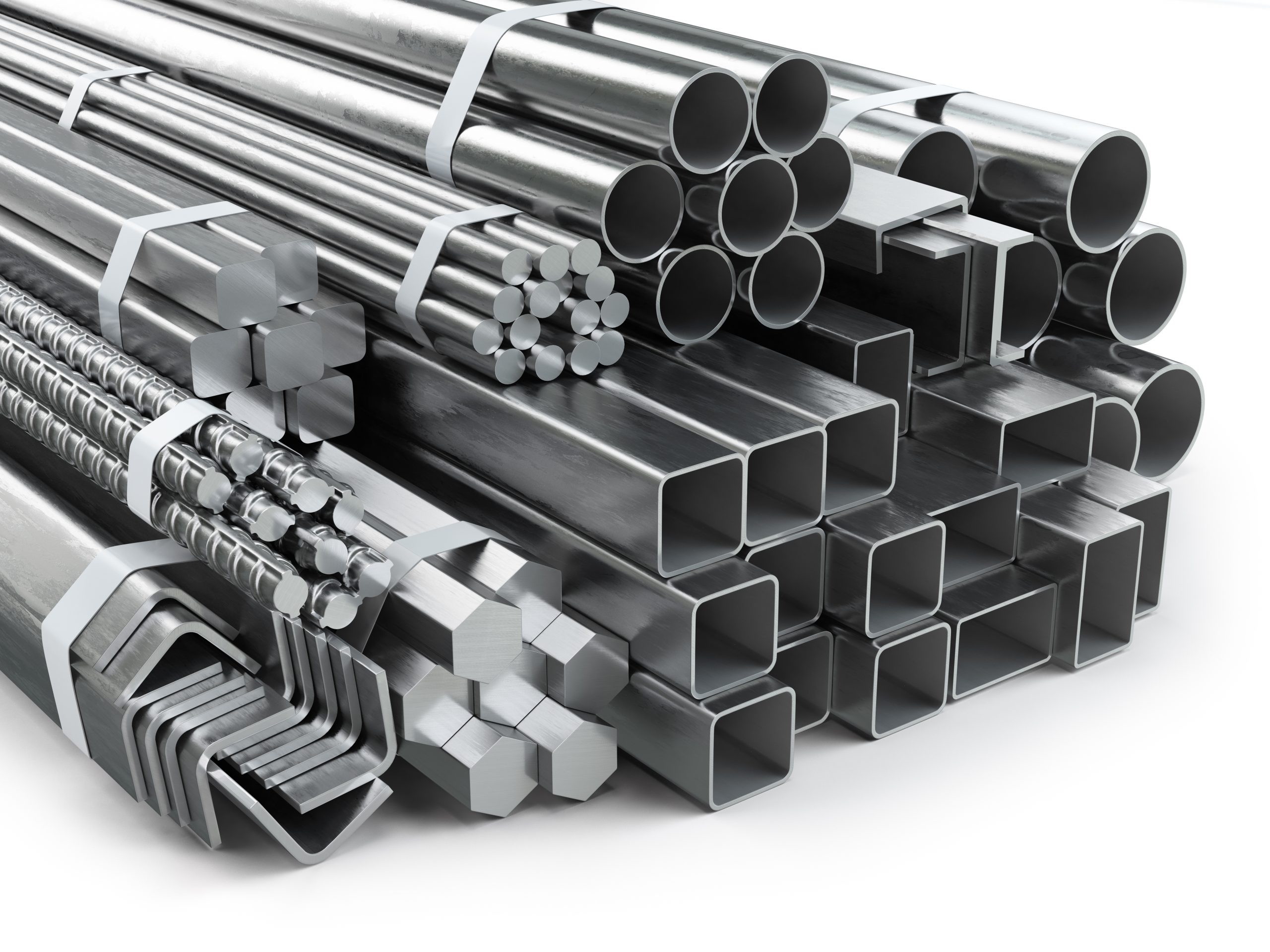

Hey everyone! Today, we’re stepping into the world of one of the most amazing materials ever discovered – stainless steel. This isn’t just about a shiny metal; it’s a story of innovation, accidents, and a material that has changed our world in more ways than one. So, let’s dive into the incredible story of stainless steel!

1913 wasn’t just another year; it was a landmark moment in the history of materials science. This was the year when stainless steel, a material that would revolutionize countless industries, first made its appearance. But the journey to this discovery was as remarkable as the material itself.

Enter Harry Brearley, a metallurgist from Sheffield, England. He wasn’t just any scientist; he was a man on a mission to solve a practical problem – erosion in gun barrels. Little did he know that his work would lead to a discovery far beyond the scope of his original project.

It was while experimenting with different steel compositions to solve the erosion issue that Brearley created a steel with a high chromium content. Upon noticing that this steel did not rust like others, he realized he had stumbled upon something revolutionary.

Initially, stainless steel wasn’t about culinary tools or construction materials. Brearley’s focus was on improving weaponry. But the accidental discovery of rust-resistant properties of this chromium-rich steel shifted the narrative from military applications to everyday use.

Brearley’s experimentation led to the understanding that adding chromium to steel at over 10% would create a corrosion-resistant alloy. This was a groundbreaking realization in an era where metals were prone to quick degradation.

The significance of this discovery quickly became apparent. Brearley understood that a material resistant to staining and rusting could have widespread applications, far beyond the gun barrels he was initially trying to improve.

In the early 1900s, the world was rapidly industrializing. There was a growing need for materials that could withstand the new demands of technology and industry – materials that were stronger, more durable, and resistant to the elements.

Traditional metals used in manufacturing, construction, and everyday items had limitations, especially in terms of resistance to corrosion and wear. The industrial age was in desperate need of a material that could endure these challenges.

Stainless steel came as an answer to these challenges. Its durability and resistance to rust and corrosion made it ideal for a range of uses, from building skyscrapers to crafting kitchenware.

One of the first commercial applications of stainless steel was in cutlery. The material’s resistance to staining and rusting made it perfect for kitchen use, a significant improvement over the easily tarnished silver and nickel cutlery of the time.

From cutlery, the use of stainless steel quickly expanded to other areas. It found applications in the manufacturing of surgical instruments, household appliances, and construction materials, among others.

The discovery of stainless steel aligned perfectly with the needs of the modernizing world. It became synonymous with progress, innovation, and the forward march of technology.

The discovery of stainless steel happened during a period of rapid industrial growth. The early 20th century was marked by groundbreaking advancements in technology and manufacturing. This era demanded materials that could meet the challenges of new and evolving industries.

Sheffield, England, where Harry Brearley worked, was at the heart of these developments. Known as the ‘Steel City’, it was a hub of innovation and metallurgy. The city’s environment played a significant role in nurturing the minds that would lead to the discovery of stainless steel.

This period was a crucible of innovation, with scientists and engineers pushing the boundaries of material science. The discovery of stainless steel was not just a standalone event but part of a larger movement that sought to transform the way we build and create.

The outbreak of World War I marked a turning point for many industries, including metallurgy. During this time, the demand for materials that could withstand harsh conditions and wear was at an all-time high.

Stainless steel, with its unique properties, quickly caught the attention of military manufacturers. Its resistance to corrosion made it ideal for naval applications, particularly in the construction of ship hulls and submarine components, which were prone to rust in the salty sea environment.

The urgent needs of war acted as a catalyst, accelerating the development and production of stainless steel.

Manufacturers began to understand and appreciate the material’s value not just for its resistance to rust, but also for its overall strength and durability.

This led to its increased production and use in a variety of military equipment, from weaponry to vehicles.

The advent of World War II further cemented stainless steel’s role as a critical material. The war’s expanded scale and technological advancements meant an even greater reliance on materials that could endure extreme conditions.

Stainless steel was used extensively in aircraft manufacturing, particularly in engine parts, exhaust systems, and other components exposed to high temperatures and corrosive environments.

After the wars, the technologies and materials developed for military purposes found their way into civilian life. Stainless steel was no exception. Its mass production during the wars had lowered costs and improved manufacturing techniques, making it more accessible for non-military uses.

The post-war period saw a boom in stainless steel’s popularity, with its applications expanding into architecture, automotive manufacturing, medicine, and consumer goods.

The demands of the World Wars also drove innovation in stainless steel alloys. The need for materials suitable for specific military applications led to the development of specialized alloys, each tailored for a particular purpose.

These innovations not only served immediate wartime needs but also enriched the range of stainless steel available for future use in various industries.

The legacy of stainless steel in the context of the World Wars is profound. The challenges and necessities of these global conflicts propelled the material into the forefront of material science.

They highlighted its importance not only as a material of strength and resilience in times of conflict but also as a versatile and enduring material for peacetime applications.

Stainless steel’s role in the World Wars is a testament to how necessity and innovation can drive material science forward, leading to advancements that continue to shape our world long after the battles have ended.

The role of the World Wars in the development and adoption of stainless steel is a key chapter in its history. It showcases how critical moments in history can accelerate technological advancement and lead to innovations that have lasting impacts far beyond their initial purpose.

The road to the invention of stainless steel was paved with numerous experiments and challenges. In the early 20th century, metallurgists were exploring ways to improve traditional steel, but they faced limitations due to steel’s inherent tendency to corrode and weaken over time.

The game-changing breakthrough came with the understanding of chromium’s role in steel. Metallurgists found that adding chromium to steel significantly enhanced its resistance to rust and corrosion. This discovery was a turning point in the development of stainless steel.

The creation of stainless steel was not a single event but a process of refinement. Over time, scientists and engineers experimented with different compositions, adding various elements in varying amounts to achieve the ideal balance of strength, durability, and corrosion resistance.

While Harry Brearley is often credited with the invention of stainless steel, there were several unsung heroes in its development. Metallurgists and scientists across Europe and America contributed to its evolution, each adding a piece to the puzzle.

The invention of stainless steel was a result of collaborative efforts and shared knowledge in the field of metallurgy. This collective endeavor across borders and disciplines played a crucial role in advancing the material’s development.

The story of stainless steel’s invention is a testament to the power of innovation and perseverance. It highlights the importance of scientific curiosity and the willingness to experiment and push the boundaries of material science.

In wrapping up, the story of stainless steel is more than just a chapter in the history of metallurgy; it’s a narrative of human curiosity, innovation, and the relentless pursuit of progress.

From its accidental discovery to becoming a cornerstone in modern industry and everyday life, stainless steel continues to be a symbol of resilience and versatility. It’s a shining example of how a single material can revolutionize the way we live and build.

How has stainless steel evolved since its invention?

What are the environmental impacts of stainless steel production?

Can stainless steel be used in sustainable and eco-friendly applications?