Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Where is stainless steel found? This remarkable material is not just a staple in our kitchens and industries; it’s a product of global innovation and collaboration.

Today, we’re going to explore the journey of stainless steel from its origins to its role in the modern world and the top stainless steel producers. Let’s dive in!

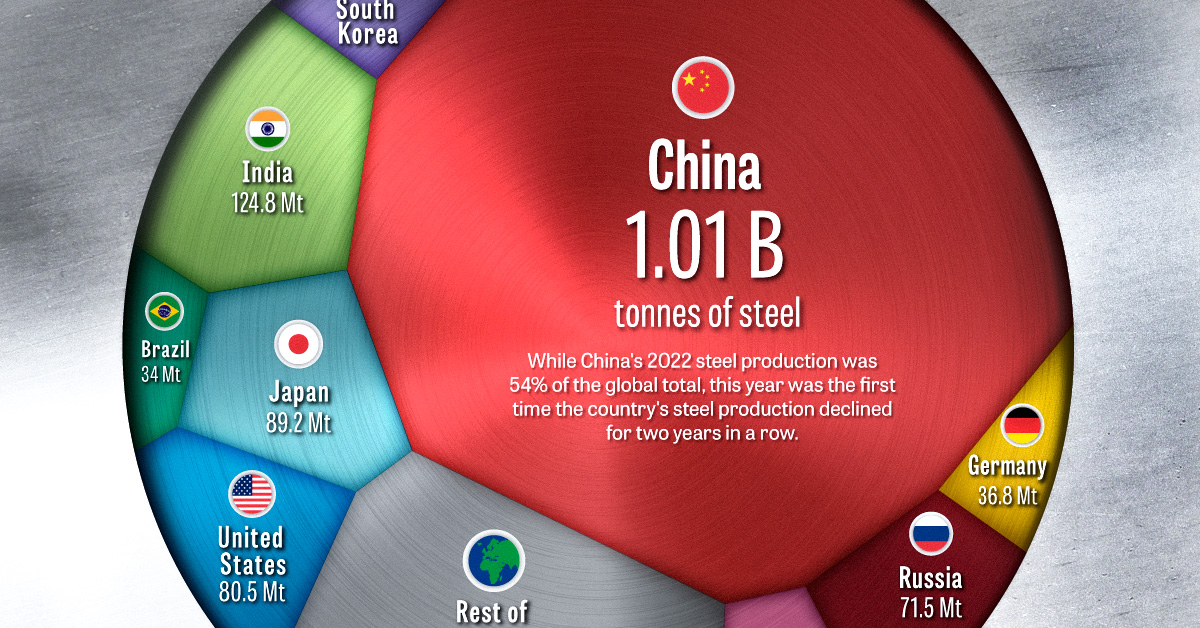

The global production of stainless steel is dominated by a few key players. China stands out as the largest producer, followed by countries like India, Japan, and the United States. The production capacity in these countries is immense, catering to both domestic and international demands.

| Rank | Country | Production 2022 (Tons) | Estimated Global Share (%) |

| 1 | China | 1,017,959,000 | 70.17% |

| 2 | India | 125,377,000 | 8.64% |

| 3 | Japan | 89,227,000 | 6.15% |

| 4 | United States | 80,535,000 | 5.55% |

| 5 | Russia | 71,746,000 | 4.95% |

| 6 | South Korea | 65,846,000 | 4.54% |

We can also see that Russia is slowly pushing its way to the top stainless steel producers due to their demand for this metal for their special military operation in Ukraine.

Overall we speculate that stainless steel production will continue to rise due to global demand by the various military industrial complexes of world superpowers due to rising geopolitical tensions.

Each of these top-producing countries has its unique strengths and specializations in stainless steel production. For instance, China’s massive manufacturing infrastructure enables it to produce vast quantities of stainless steel, while Japan is known for its high-quality, precision-grade stainless steel.

The production of stainless steel is a truly global enterprise. Raw materials are sourced from various countries, processed in another, and the final products are used worldwide. This global network underscores the material’s importance in the international market.

Several companies lead the global stainless steel industry. Notable names include POSCO in South Korea, Nippon Steel Corporation in Japan, and Jindal Stainless in India. These companies are not just producers; they are innovators in the field.

These leading companies compete not just in production capacity but also in the quality and range of their stainless steel products. They invest heavily in research and development to create more efficient and sustainable production methods.

The dominance of these companies in the stainless steel market has a significant impact on global trade and economics. Their production decisions can influence prices, availability, and the development of new stainless steel technologies.

While stainless steel itself is not naturally occurring, the raw materials needed to make it are. Countries with rich reserves of iron ore, chromium, and nickel are pivotal in the stainless steel industry. Nations like South Africa, Kazakhstan, and India are notable for their vast chromium reserves, while countries like Brazil and Australia are rich in iron ore.

Having reserves of these essential minerals gives countries a strategic advantage in the stainless steel industry. It can influence their economic stability, trade relations, and industrial growth.

The mining landscape for these minerals is diverse and expansive. It involves a complex network of extraction, refinement, and global trade, ensuring a steady supply of raw materials for stainless steel production worldwide.

The consumption of stainless steel is closely tied to a country’s industrial development. Highly industrialized countries like the United States, China, and India are among the top consumers due to their extensive use in construction, automotive, and manufacturing sectors.

| Rank | Country | Steel Consumption 2023 (Million Tonnes) |

| 1 | China | 914.0 |

| 2 | India | 120.3 |

| 3 | United States | 100.8 |

Economic development in emerging countries also drives the demand for stainless steel. As nations develop their infrastructure and industries, their need for durable and corrosion-resistant materials increases, boosting stainless steel consumption.

The demand for stainless steel is a reflection of a nation’s economic and industrial progress. It is an essential material in developing modern infrastructure, transportation, and technology, making it a key indicator of a country’s development status.

Stainless steel is much more than just a shiny metal. It’s an alloy, primarily made up of iron, chromium, and often nickel. The magic of stainless steel lies in its chromium content, which is usually over 10.5%. This chromium forms a thin, protective layer on the surface, helping the steel resist rust and corrosion.

Contrary to some beliefs, stainless steel isn’t found naturally. It’s a human-made alloy, crafted by combining certain elements under specific conditions. This ingenious creation is a testament to human ingenuity in materials science.

The production of stainless steel is a fascinating process. It starts with melting the raw materials, including iron ore, chromium, and nickel, in a blast furnace. The molten metal is then refined, cast into slabs or other shapes, and finally, rolled or processed into the stainless steel products we use every day.

Stainless steel’s unique properties come from its blend of elements. Chromium provides corrosion resistance, while nickel adds ductility and toughness. Other elements like molybdenum can also be added to enhance specific properties.

The star of the show is chromium. It reacts with oxygen in the air to form a passive layer of chromium oxide, which shields the steel underneath from corrosion and rust. This layer is incredibly thin yet highly effective, and it can self-repair if scratched.

The versatility of stainless steel lies in its varying compositions. By adjusting the proportions of chromium, nickel, and other elements, metallurgists can create different types of stainless steel suited for various applications, from cutlery to skyscrapers.

The journey of creating stainless steel begins with its raw materials. Iron ore, chromium, and nickel are combined and melted in a furnace at extremely high temperatures. This molten mixture is then treated to remove impurities.

After treatment, the stainless steel is cast into initial forms. These could be thick slabs for heavy-duty use or thin sheets for appliances. The casting process is crucial as it determines the steel’s initial shape and properties.

The final step involves various treatments like annealing, quenching, and tempering to achieve the desired strength and flexibility. The steel is then often polished or finished to provide the characteristic luster and smoothness we associate with stainless steel products.

One of the primary consumers of stainless steel is the construction industry. Its strength, flexibility, and resistance to environmental factors make it ideal for building structures, architectural facades, and interior design elements.

The automotive industry heavily relies on stainless steel for its durability and resistance to corrosion. It is used in a variety of components, from exhaust systems to decorative trims.

In the medical sector, stainless steel’s hygienic properties make it indispensable. It’s used in surgical instruments, medical devices, and hospital equipment for its ability to be sterilized without corroding.

Stainless steel is a backbone of modern infrastructure. Its use in bridges, railways, and public buildings not only provides structural integrity but also adds to the aesthetic value of these constructions.

In the realm of technology, stainless steel plays a critical role. From household appliances to advanced computing and mobile devices, it provides a combination of functionality and sleek design.

With the world moving towards sustainable development, stainless steel is becoming increasingly important. Its recyclability and durability align with the goals of eco-friendly construction and green technologies.

The journey of stainless steel from an accidental discovery in the early 20th century to its global use today is a story of innovation and adaptation. Its development paralleled significant industrial and scientific advancements, making it a material that mirrored the progress of the modern age.

Over time, the alloys of stainless steel have evolved, adapting to the changing needs of industries and technologies. This evolution reflects the dynamic nature of material science and its response to global challenges.

Stainless steel is more than just a material; it’s a symbol of an era defined by rapid industrialization and technological progress. Its history is intertwined with the story of modern civilization.

A common misconception is that stainless steel can be found naturally. However, it is not a naturally occurring material but an alloy created by human ingenuity.

Stainless steel is made by combining natural elements like iron, chromium, and nickel in specific proportions and under controlled conditions. This process of alloying is what gives stainless steel its unique properties.

The creation of stainless steel is a testament to human innovation in material science. It showcases our ability to manipulate natural elements to create materials that meet our specific needs and challenges.

In summing up, stainless steel’s journey from an accidental discovery to a cornerstone of modern industry and everyday life is a fascinating tale. It highlights the ingenuity of human material science and our continuous quest to improve and innovate. From towering skyscrapers to the cutlery in our drawers, stainless steel continues to play a vital role in our lives, combining strength, beauty, and versatility like no other material.

Is stainless steel eco-friendly?

What are the latest trends in stainless steel production?

How can consumers recycle stainless steel products?

And there we have it – a deep dive into the world of stainless steel. From its inception to its global impact, stainless steel has proven to be a material that not only shapes industries but also reflects the progress of our society. Stay tuned for more insights into the fascinating world of materials and innovation!